Your Personal Assistant – The Blower Sizing Tool

Blowers consume around 60% of the total energy used in the wastewater treatment plants, therefore they have a significant impact on the operational expenses. The efficient blower sizing is a key element even in the preliminary design stage.

Blowers are widely used in multiple positions in the wastewater treatment process, such as for grit removal, biological reactors, membranes (in case of MBR) or sludge storage tanks.

There are 5 blower types used in the industry:

- Positive displacement /Rotary lobe

- Dry screw

- Multistage centrifugal

- Single stage integrally geared centrifugal

- High speed turbo gearless

Each of these has its own advantages and disadvantages and the blower selection process includes proper evaluation of these factors. The type of the blower determines electricity consumption, maintenance estimation, investment, and replacement cost. But the electricity consumption is just part of the evaluation. Outlet air temperature, noise, footprint, or weight can also be important depending on the project’s characteristics.

We developed a free tool for wastewater engineers to be able to do quick calculations on blower sizing. Let’s see a real-life example of how to use the tool.

Select best blower type for biological reactor

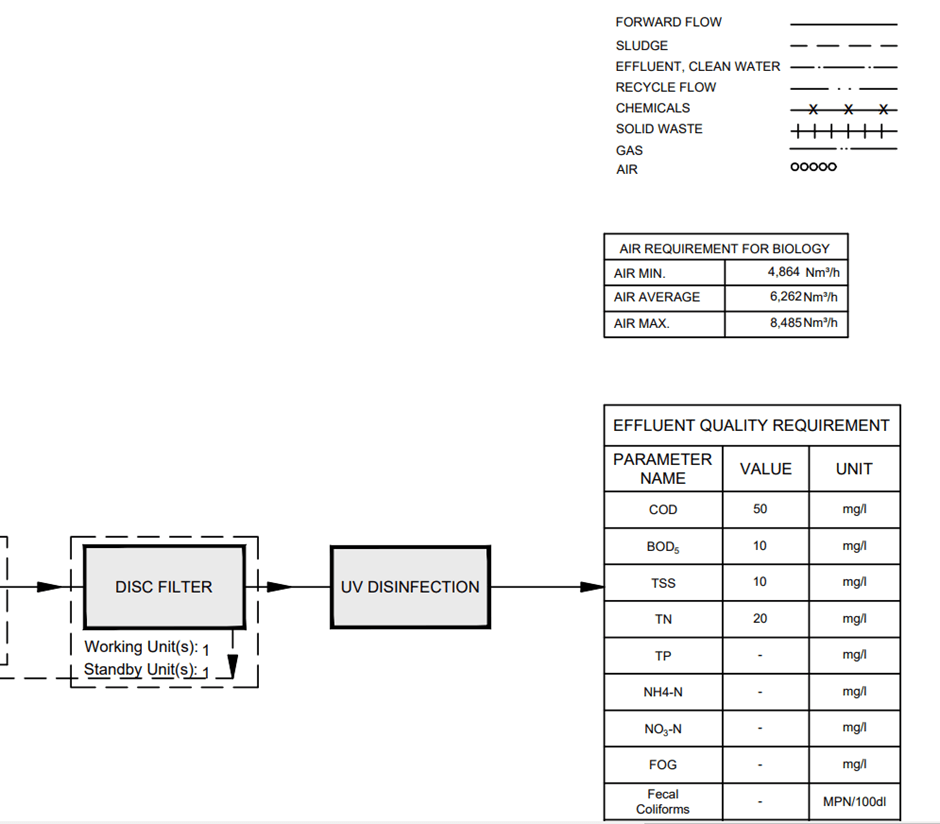

If the engineering team created the Process Scheme for the wastewater treatment plant, the air requirement for the biological reactors should be also calculated. If you created the design with Transcend Design Generator, the air requirement value can be found on the right side of the Process Scheme as shown in the below picture.

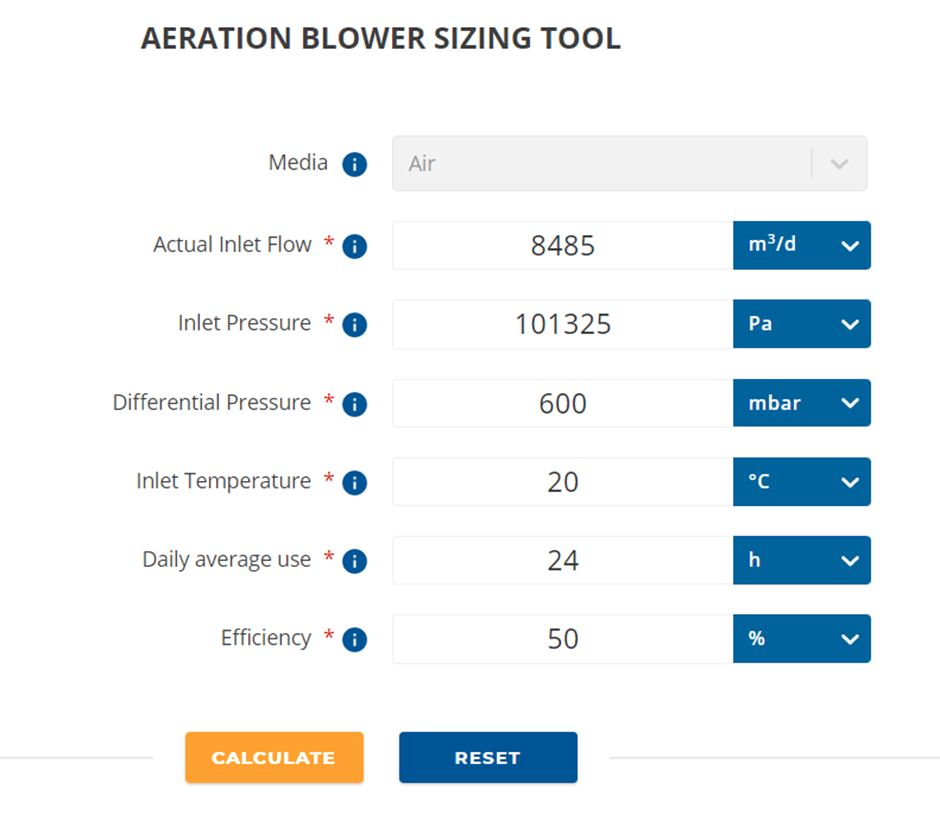

You can take this value and insert it into the Blower Sizing tool. In this specific example, we will do the calculations for the max air requirement and inserted 8485 m3/d into the calculator and assumed 600 mbar differential pressure, based on the 5m depth of the reactor. ( 5m * 9.81 m/s * 1000 kg/m3 = 490.5mbar, and we consider 109.5mbar for pressure loss on the diffusers and on the pipe).

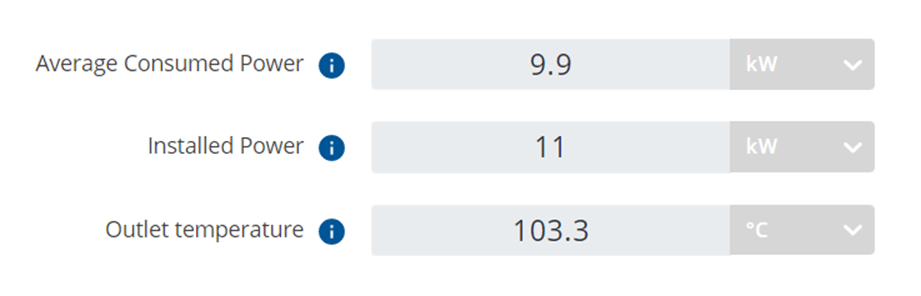

In Scenario 1, the efficiency was set to 50%, as a trial for Positive Displacement w/VFD blower type. The result is the following:

It’s important to note that the energy consumption is calculated based of adiabatic theory, while the temperature rise is calculated in both adiabatic and polytropic way, and the higher is selected to be on the safe side.

After creating 4 scenarios, we can create the below summary table:

| | Scenario 1 | Scenario 2 | Scenario 3 | Scenario 4 |

| Efficiency | 50% | 65% | 75% | 80% |

| Avg Consumed Power | 9.9 kW | 7.6 kW | 6.6 kW | 6.2 kW |

| Installed Power | 11 kW | 11 kW | 7.5 kW | 7.5 kW |

| Outlet Temperature | 103.3 C | 84.1 C | 75.5 C | 72.1 C |

| Blower type | PD w/VFD | Multi-Stage Centrifugal | High Speed Turbo Gearless Centrifugal | Single Stage Integrally Geared Centrifugal |

We can use this comparison table to support our blower type selection process. Average consumed power provided by the Blower Sizing Tool is a suitable estimation in the preliminary phase’s opex calculation, as both processes and mechanical requirements are built into the calculation. Exact consumption data will be provided by the manufacturer upon selection.

The other outcome of the tool is the outlet temperature. According to the laws of thermodynamics, we can take the assumption that the higher temperature requires more durable instrumentation or piping elements, which can also imply additional cost. The outlet air temperature can also have other effects on the design, for example, reactor depth or pipe length. In our next use case, we will be presenting how the blower sizing tool can help to find the optimal reactor depth and energy consumption of the blowers. In the meantime, feel free to share your thoughts on how you utilize the Blower Sizing tool.