What does the term ‘digital twin’ mean in the context of water and wastewater? Why is it important? Why is design such a critical component? Our COO Steve Davis sat down with our Director of Software Solutions, Adam Tank, to discuss this exact topic. Enjoy!

Adam

First question – what does digital twin mean to you in the context of water and wastewater?

Steve

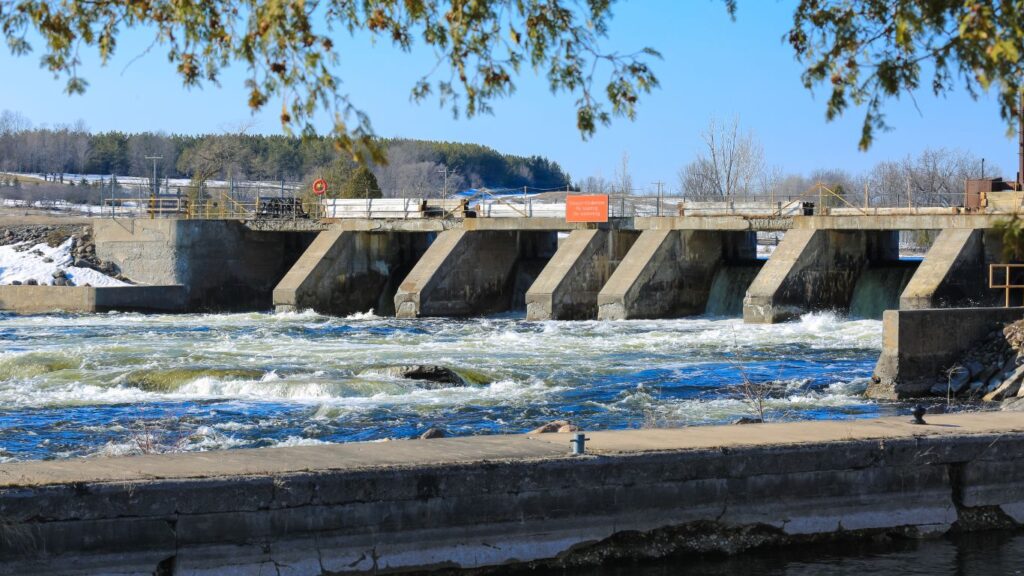

In the context of water and wastewater, the digital twin has a lot of different definitions. My opinion on it – it’s the ability to use data that allows you to understand how either a physical asset, or a group of physical assets, interact with one another. And more specifically, the ability to understand what the basis of operations is or the “status quo” of how those assets were designed to operate. You also then have the ability to then run simulations to understand and report on how well those assets are doing, and how much capacity those assets have.

Steve

In either the physical asset or the collection of those assets as a given facility, the twin is really your benchmark to run those simulations and analyses on. In water that could be a blower, that could be an MBR tank, or it could be an entire wastewater facility – it’s about how all of those assets come together and the performance of those.

Adam

So when an asset owner or an engineering firm or a technology firm says we’re going to do digital twin, let’s say for wastewater in this case, what are the outcomes they’re trying to drive towards, what’s the end goal?

Steve

The end goal is to be able to run and operate a given facility at its most optimal point at any given time. You’ll know how you should be running the facility right now based on current demand and then also be able to understand what you should do for future scenarios. So whether that’s in five minutes, or five hours, or even five days, a great digital twin should be able to predict those future scenarios and then optimize the operation to be as efficient and effective as possible.

Steve

By the way – that could mean the use of people, not just the use of the physical assets.

Steve

If you can operate the facility at the lowest total cost with the least amount of energy that’s needed – both human energy and actual energy cost – and chemicals, sludge… Then you’re winning. That’s what the outcomes need to be.

Adam

Would you say the goal is minimum number of inputs in terms of people, money, energy, et cetera, with the maximum effect, the maximum output?

Steve

Optimized, not maximum. I think that any given asset has a max limit to it, it has what it should be running at and it has probably a minimum limit to it.

Steve

Your goal is to allow the operations to have a moving target, but also allow the controls of those assets to move with those targets and those ranges. And the better you are at using your digital twin to represent what those situations are, the more optimal that you’re going to run.

Adam

You know better than most… when we were at GE there was talk of digital twin in 2012, 2013…

Steve

Definitely, or before that.

Adam

Do you think the vision of digital twin as you see it, or maybe as GE saw it or anyone talks about it, has fully been realized?

Steve

There’s no way that I’ve ever seen anybody fully realize digital twin in any real capacity, and there are several different roadblocks to that.

Steve

To give you examples, some people who don’t know necessarily what they want to achieve and they don’t understand what a digital twin is all about. And if they don’t understand those and they don’t have the right tools, or the right data, or the right information and the right people to help guide them through that transformation, they’ll never get there. And I honestly have not seen anybody necessarily get there in any shape or form today.

Adam

How much money do you think has been spent, or how much money was spent by a company like GE on this concept?

Steve

Millions. Probably tens of millions of dollars was spent on digital twin. I would say in the best case it’s outside of water. I think GE’s case and how they utilized it for gas power plants was probably the best and probably where I’ve seen it most commonly used and actually applied appropriately. You know, gas engines have gotten to a point where you can run them man-less, you can run them effectively, efficiently, down to nearly the penny for lack of a better term.

Steve

Whereas I don’t think you or I have ever seen a wastewater or water facility ever optimized to that point.

Adam

So as you see something like gas engines that are optimally running based on a digital twin, why has that been successful and why has water not been successful? What can water learn from that example?

Steve

I think the water industry is much tougher than the gas engine industry in the way that gas turbines, in relative terms, are newer than a wastewater facility or a drinking water facility. So in the gas energy industry they have a basis of design, they understand what the physical assets are at a site, who was thinking about designing that physical asset, what it was designed for, what were the design ranges… they understand the building materials or the BIM model for that site, and they understand all the interdependencies of a given gas facility.

Steve

In a water facility we lack a ton of that data. Operators keep that in their head. They’ve done their own testing in terms of limits. They failed a lot of times (in a positive way – because that’s how you learn). But that data resides typically in a person’s head. And because of it residing in somebody’s head, you need to sort of digest that and you got to figure that out. That’s one avenue to tackle. I say the other avenue is to sort of go back and reverse engineer what you have on site and and understand the basis of it.

Steve

And then from there you could create your baseline. And you can create the predictions, you can create the “the operational envelope” for the plant and then you can start to optimize based on those things that we talked about earlier.

Adam

Though in the case of the water industry you mentioned that we don’t have the required data… and the data we do have might not be digital data. Like you said it could be in an operators head, it could be on a piece of paper somewhere. It could be whatever the specs are for a given piece of equipment…

Adam

What would you tell someone who’s considering to start this process, someone who says “alright, we’ve got a budget and we want to start on this concept of digital twin. We have an existing plant. Where do we start?”

Steve

Before I get into that one, let me give you one other one that you and I worked on together.

Steve

People wanted to reduce non-revenue water. And one of the most important things to start to do that is understanding your pipe network. If you produce a million gallons of water, you should be able to account for a million gallons of billable water. And if you start at the most fundamental thing, it needs to be, well, what’s the transmission of that water? And, you know, you and I went through that.

Steve

There was no company that we could find in North America, at least, that had not just the mapping of where the pipes are… But the age, the materials, or construction date. What was the lifespan supposed to be for that asset? What was the break fix history of that piping?

Steve

If you look at that example, I think that’s sort of the foundation. So you first have to figure out where are you going to focus first? If you’re in the water and wastewater industry, you’ve got to figure out, OK, are my biggest issues in the facility? Is it in the infrastructure? Is it in the metering? Is it on the billing side? Once you first decide on what you’re going to tackle, then I think you can start to go into the nuts and bolts of, OK, what information do I need, where are my gaps at, and then how do I make up that gap?

Steve

Again, to stick with the non-revenue water example, you’re getting that data around pipe locations, sizes, materials or construction, age of installation, maintenance, history, and getting that all gathered together into a usable format so that it can be analyzed and create a baseline.

Steve

We’ll then start to apply techniques where digital twin has value. Predicting where you should be investing in that infrastructure – where you should be implementing district metering, where should you be doing robotic scans in the pipes. Where you should have a proactive “I’m going to go replace these pipes now or these valves before they break, because we know every year we’re doing X amount of these.”

Steve

That’s on the piping side. If you shift and look at a wastewater facility, you want to first look at do you have the data on the physical assets – the clarifier size? The retention time of the plant? The blower capacity? The types of blowers you have, the type of biological assets that you have or screens or grit chambers. Get all that information, understand where your biggest hurdles are from efficiency, start the baseline and then start to figure out where your plan is to optimize.

Adam

Let’s say you are building a plant from scratch… or maybe not even from scratch… let’s say you’re expanding one or rehabilitating one, and you have a good idea about the condition of the assets on site or the constraints of the site that you’re building on. Can you move forward on digital twin? I see this term digital where digital is a critical component -do you need to be thinking about the sensors and what equipment has a sensor on it and the equipment data that each sensor is collecting? Or should you start at some other level?

Steve

I think analyzing what’s your manual data? What’s your manual lab data? What sensors do you have? What controls do you have? This is definitely the baseline. Get what you know you have and validate that it’s good data – you know, garbage in, garbage out in terms of data.

Steve

Once you’ve done that analysis and you also know where your gaps are then I think investing in the sensors, the minimum package of sensors, is a requirement these days. I don’t think it’s an option now anymore.

Steve

You need to know your effluent flow. You need to know the total suspended solids or the ammonia limit or the ammonia reading or nitrogen. You need to have these sensors. In my opinion, they’re not optional. They give everybody a sense of transparency and they give the real story of what’s going on in the operation. I don’t think incorporating sensor data into your operations is ever going to change.

Steve

If anything, people are reinvesting in those, whether it’s a new add on or whether it’s in your existing plant.

Adam

Let’s talk about the interaction between design and what’s actually built. Design as I see it today is mainly digital – I mean, you might have a ‘napkin’ sketch at some point, but for the most part, stuff is designed digitally. So we’ll say as-designed vs. as built. You mentioned the gas engine example – you said that from the get go, they have a very clear understanding of the design of each asset, but also how those assets work together. And that in water, wastewater, they don’t.

Adam

So where where is the intersection between the design of the plant or the facility or the upgrade or a single asset versus what’s actually built, and what’s sensored, and where the digital data aspect comes in for a physical built environment?

Steve

That as-designed versus as-built data is super critical, whether it’s the existing or the future assets that you’re going to put together.

Steve

In the world today, especially around digital twin, the foundation of what you’re going to be able to model and how well you can start to get into that optimization realm relies on getting that data right. So sizing, capacity, volumes, throughput, energy, opex, you know, those things have to come into play and you should demand that data on any new asset. And if you’re investing in digital twin, it should be one of your first investments.

Steve

In the water industry plenty of consultants, plenty of engineers, go out and do site audits. And these site audits are tremendously valuable. But in many cases, people take that site audit and they use it for a one time event and that site audit gets filed, put away. And it’s stored just like all the blueprints or PDF’s that are sitting in some filing cabinet, whether it’s electronically stored or not. The purpose of that audit is that that’s all valuable information that should be used going forward.

Steve

To put it another way, if you were to go back five years ago and look at a retention basin, it was just a retention basin! That’s all it was for, that was the main purpose. There was no goal other than to have a retention basin.

Steve

Now those types of assets are being thought of more as, OK, I have capacity here, how can I use that capacity? How can I actually, you know, divert flow into one of those basins to help optimize the operation of another given asset? So you’re starting to put things into perspective, getting the data around those assets and starting to think differently on how you use them based on the design is critical. It’s all a network.

Steve

As you think about the physical asset as a part of the collection of assets, having that design data will allow you to start to look at the bigger picture and then really optimize, again, the whole wing to wing network and everything that’s in between.

Adam

Let’s assume you have an existing wastewater treatment plant. You are trying to determine what the optimal operation of that facility is on an aggregate, on a whole scale, like when the influent comes in and the effluent goes out, what is the optimum way for this thing to run? Can you do that without design data? Can you just take the assets that are on site, collect the data, figure out where the gaps are, throw sensors on everything, and create an optimum operating environment?

Steve

My answer is no on that. I think you need to have some type of engineering design work done.

Steve

If you collect the physical asset data of your wastewater from wing to wing – influent to effluent, you collect all that information, you should be able to, traditionally, give it to a consultant or engineer, allow them to understand the hydraulic flows, go through each of the assets and understand how everything is connected physically and also with biological constraints and things like that.

Steve

Now moving in a direction that connects to what we do at Transcend – you could get 80 to 90 percent of the way there without a big engineering study. With an instant conceptual design you can take and look at the facility and say, OK, yeah, these are the assets I have. Here are the assets that operate and here’s the capacity I have, here’s the efficiency I should have at every stage in a given process. The interesting piece is that along with digital twin, the digital design points out your areas of failure and those that are most constrained. That’s where you can go and get an engineer involved or another tool to say, OK, I need to upgrade, you know, this component, this physical area.

Steve

And by upgrading this area and by investing this capital, these are the gains the investment is going to give me. And it’s not just answering questions like what if I have an increased flow rate, or I have nutrient removal, or an effluent constraint. It can also be wet weather events like what to build if I’m having overflow. So it’s minimizing your risk of failure.

Steve

You need to have a design basis, you need to have a process scheme. You need to have a design philosophy, whether it’s an existing plant or not. And it has to be documented. It has to be part of your digital twin to understand how you’re going to operate in the future and how to optimize and make your plant more resilient.

Adam

So you’re saying that in the case of an existing wastewater treatment plant – let’s say you’re collecting all the data from all of the assets and you have a digital twin of how that environment or system currently operates, that can be done. BUT, for that whole system to operate efficiently across a wide range of scenarios, so be it bio-p or peak wet weather or dry weather or name your next event that’s going to occur at some point in the future… You have to have the design because that enables the simulation, that enables the optionality assessments, that answers all the “what if” scenarios that might happen.

Steve

The design data allows you to run all those simulations before investing that capital – it allows you to answer all of those “what ifs.” And then if you get the design and digital twin in “automatic mode” it doesn’t matter what future event happens, it will tell you how to maneuver the levers that you have within that plant to operate and run at peak efficiency. Again, that might be a different operational strategy than what you’ve had in the past. But it doesn’t matter what event that is, you don’t have to be in the plant and running around trying to control things reactively.

Steve

You’re proactive. The system is proactive. Going back to the example with gas turbines. You have a huge event coming in like a storm or hot weather, which is the best one, red hot weather, and know your demand is going to go crazy. In gas engines they know, “hey, I’m going to have to be at one hundred and fifteen percent for the next four days during this event, and then I’m going to turn back down the 80 because the temperatures reduce. I’m going to have to shed some power.”

Steve

And it knows it without a human having to even come close to making a decision like that. And it gives that decision support to the operators. So it’s that digital twin enabling you to know I can at one hundred and fifteen percent during this time, I don’t need to be worried, I don’t need to sweat it. But I also know I’m going to be running efficiently at one hundred and fifteen percent, just like I would if I was at 60 percent.

Adam

And you’re saying that this system is designed that way? It’s designed to be resilient. It’s not something that happened after the fact based on a collection of data? Design data from before it was even built, an engineer was able to say “we are designing it so it will operate efficiently at one hundred and fifteen percent, just as it will operate efficiently at 60 percent.”

Steve

Yes, and in the gas turbine industry everyone ships out with that design & digital twin model, but they’ve also been able to take that same model and go back to older facilities and implement something that’s nearly as good. Because they’ve gone through that same analysis that we just talked about with wastewater.

Steve

They did the audit. They got all the information. They went back and looked at the design information, the past audits, any documentation. They figured out how that asset and that group of assets is supposed to be run. And they’ve created that baseline and those envelopes of operation.

Steve

Once you have that, it doesn’t matter if it’s a gas turbine, or if it’s a wastewater facility, or a drinking water facility… That is the foundational structure of what you need to start to move in a direction that allows you to get to a digital twin, simulate and optimize.

Adam

Let’s talk about Transend for a second. What do you see the benefits of Transcend software relative to people trying to implement digital twin? We’ve sort of circled around it like we haven’t really hit the nail on the head.

Steve

I see two major plays.

Steve

One – if you don’t have a baseline and you don’t understand what’s going on and you need to start with a baseline or get a baseline. One really easy way to do that is to plug in your average flows, plug in your some of the information in terms of how many trains you have, what your reactor size is… put in all that core information and run a design in Transcend software. That’s going to get you 80% percent of the baseline you need.

Adam

You’re saying without any other asset data, without any real time monitoring, without any censoring in the network, without any of that stuff, you’ll still get 80 percent of the way there with an existing facility.

Steve

Yes. The next 20 percent is critical because you can’t really start until you’re closer to probably 90 percent. So the next piece of it is taking that design output and really going into the plan with those operators, taking the walk, doing the audit.

Steve

Hey, is this the size blower that I have? Yes, it is right. It’s wrong. It’s incorrect. I’m changing this. OK, so go and collect that data, validate what’s there. See what’s correct and what’s incorrect, and then do an adjustment based on those things. Once you do that adjustment and you baseline everything now you’re really close to setting up your foundation for digital twin. I’d say you’re near that 90 percent.

Steve

Once you have that, though, the next step to actually running a digital twin, you need to now start to build on on top of that baseline. Just because you have a digital twin doesn’t mean you’re getting anything. Now you need to be running more efficiently. So taking the baseline and then changing your control algorithms would be one example.

Steve

So that’s a first step or one way to use Transend, and that’s a big step towards digital twin.

Steve

I’d say the second way Transcend can be used is to deal with constraints of an existing digital twin. If your digital twin is saying, hey, I can’t handle this flow rate, you cannot do this with this given set of assets – you’re completely limited and the twin says do not exceed this, you’re in the red here. Fire engine red. You as the asset owner or engineer should start to think about what to do to fix that, right? How do I achieve a design that’s going to get me to having more flow or a different operating limit?

Steve

If you run the Transcend Design Generator, you could now plug in those new constraints and have your answer instantly. Here’s an example.

Steve

There was an area in Maryland, they just put in a brand new Amazon facility and their population growth went up tremendously within a year. Huge boom, tons of wastewater produced now. They have this little plant because they’re a little town. Their digital twin might have been running perfectly, but now they’re exceeding the limits of the plant all the time. What should they do?

Steve

Traditionally you’re going to call up an engineering firm and say “hey, come in and do a study.” That study is going to take a year. They’re going to charge you a hundred thousand dollars. They’re going to send it into the community and say here’s a proposed budget. And that budget is normally just a 30 percent design with an idea of what they can do to meet the new wastewater demand.

Steve

And you’re going to get approval for a given budget and you had to spend a bunch of money to get there. With Transcend you can go into the software, plug in your new limits, select the type of technology you’re currently using, or select others as alternatives, hit go, and come back in a couple hours and you can see a design output.

Steve

You could then align that with what assets you currently have – and say “Oh, I already have these assets, I just need to add more capacity in my clarifier, a bigger equalization tank, and five new blowers. That’s one option.

Steve

Second option. “Oh, wow, there’s an innovative company out there that’s doing this new MBR technology. I could put those MBR’s in, I can add one more tank of them and not only can I meet the increased flow rate, but I could also do better on my effluent limits… Which I know for a fact that whether it’s today, tomorrow, or in 12 months, I’m going to have more stringent effluent parameters.

Steve

So you can actually kill two birds with one stone during this and you’re going to do it for pennies on the dollar and in a fraction of the time. You can get your own general estimates as you wish and you can go to the board with some detailed, high quality engineering documents. Those are the two ways that you can use Transend software or an automated design software to help with your digital twin work that you’re doing, or should be doing.

Adam

How far does Transend software get into the the data layer? Will it provide details for how best to collect the data in a plant to create a digital twin of the operations?

Steve

No, Transcend doesn’t give you the best data collection strategy. But there are some really good best practices that are out there today from the EPA and they are getting better every day.

Steve

They have really good standards on what data you should be collecting and there are a lot of really good people in the industry that can help guide you through the data collection and how to automate operations. At Transcend our focus is on helping people to really understand that design foundation.

Steve

If you get that wrong you cannot get going on any of the digital twin work in an effective manner. Any facility that’s out there, it needs to have that baseline. And I would tell you that the vast majority don’t have a good baseline today.