Midsize US engineering firm used TDG to proactively suggest facility upgrades to utility

A mid-sized engineering firm used TDG to proactively suggest facility upgrades for a utility client, efficiently generating multiple design alternatives for secondary clarifier improvements. This approach not only reduced design time from 25 days to 1 day but also strengthened the firm’s relationship with the utility and positioned it favorably for future project tenders.

Introduction

Transcend Design Generator (TDG) offers a transformative solution for engineering firms in the critical infrastructure design industry. It addresses the growing need for efficient, innovative design while reducing the burden of non-billable engineering hours during new business pursuits. TDG streamlines early project stages by automating monotonous design aspects, enhancing margins, and freeing up engineers for more creative, cost-recoverable work.

TDG enables firms to provide more value to clients, pursue more projects, and grow their business by improving response times and offering more detailed options in the early stages of design.

Here, we introduce a specific use case for TDG for engineering firms looking to proactively drive business development and set themselves up for successful bids.

Situation

While working on a screening and grit system upgrade for a utility client, a mid-sized engineering firm learned of the client’s need to evaluate secondary clarifiers at two facilities, in increased future flow. The firm proactively presented solution alternatives using TDG, aligning with the client’s capital planning cycle. This approach aimed to deliver value and strategically position the firm for future tenders.

Who

Project Manager: Coordinates project execution and communication between the engineering team and the utility client.

Process Engineer: Specializes in evaluating and designing processes for wastewater treatment facilities.

Civil Engineer/Architect: Assesses structural feasibility for facility upgrades and new constructions.

BDR: Manages client relationships and aligns firm offerings with client needs, facilitating the sales process.

Task

The engineering firm seeks to determine:

-

The capacity of secondary clarifiers to handle increased flow.

-

Current performance and design adequacy of the secondary clarifiers.

-

Feasibility of incorporating new assets within existing site constraints.

Action

These questions can be answered by running multiple designs, or ‘optioneering’.

The Process Engineer runs five design alternatives in TDG for two facilities, focusing on current and future flow capacities. Alternatives also include evaluating MBBR for one facility that has footprint constraints.

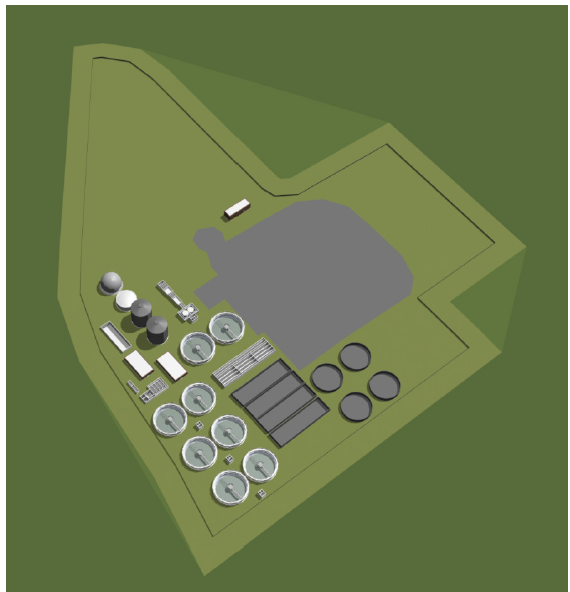

TDG output documentation is generated within a day, and the engineering team reviews the documents which include process schemes, technical descriptions, P&IDs, equipment lists, 3D BIM models, and cost estimates.

Results

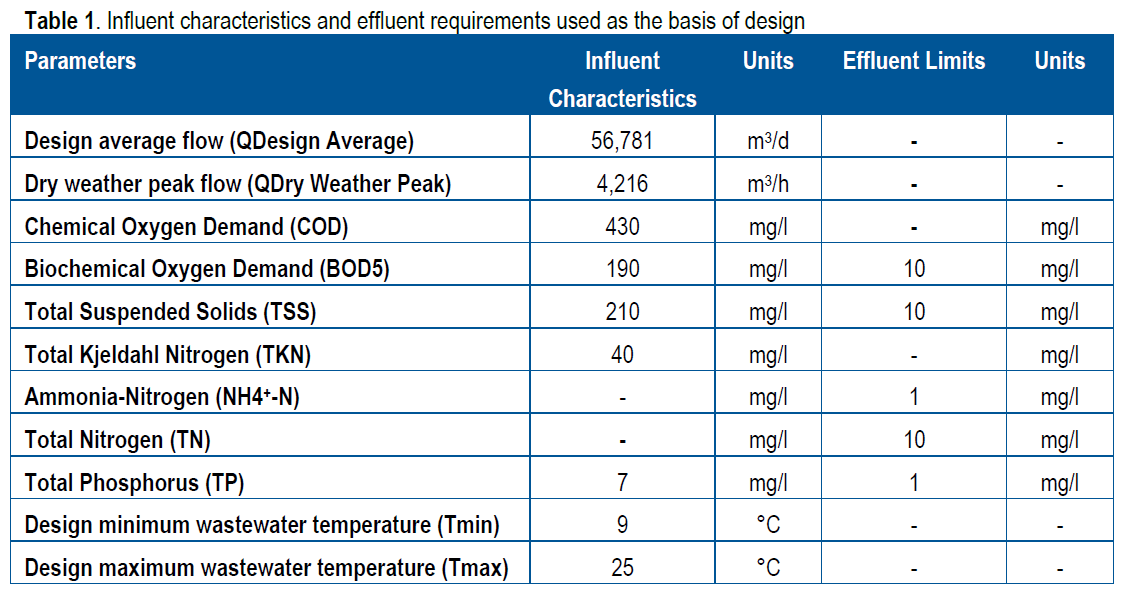

For one facility, it was determined that the existing secondary clarifiers are adequate for both current and future flows.

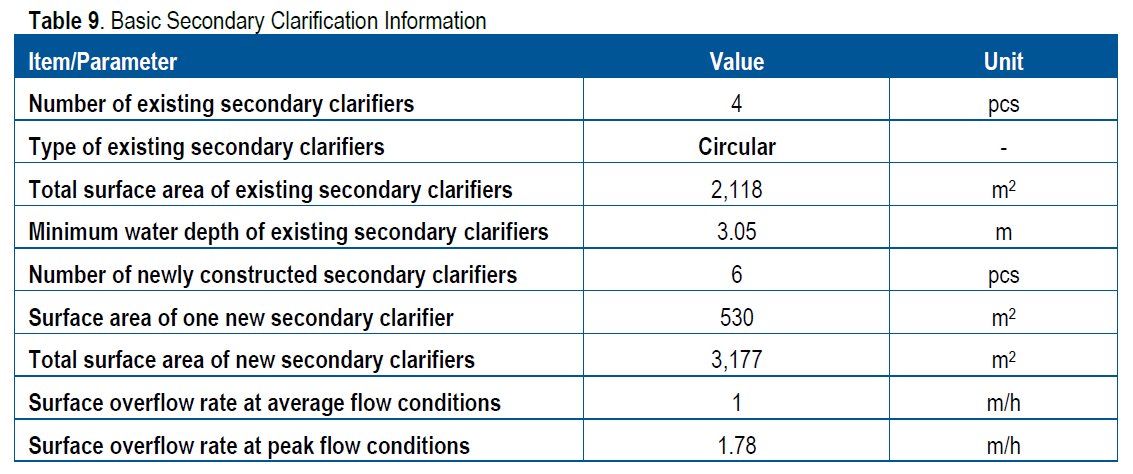

The second facility, however, was identified as nearing capacity and would require the construction of six new secondary clarifiers to accommodate future flow. An MBBR expansion was recommended for a more compact design compared to CAS.

The firm presented these findings to the utility, who was highly appreciative and initiated planning for the expansion project at the second facility in their next year’s Capital Improvement Plan (CIP).

Going Forward

-

Utilizing TDG, the time required for conceptual design output was dramatically reduced from an estimated 25 days (5 days per design) to just 1 day for all five alternatives.

-

This efficiency enabled the engineering firm to feasibly generate proactive proposals, which would have otherwise been impractical due to the extensive non-billable hours required.

-

The firm fostered trust and added value to the utility, strengthening the potential for a long-term partnership.

-

The firm is now well-positioned to collaborate with the utility in scoping out the expansion for one of the facilities and stands a strong chance of winning the bid once it is issued.

WWTP Design

WWTP Design  Substation Design

Substation Design  Utility Interconnection Hub

Utility Interconnection Hub  White Label Proposal Generator

White Label Proposal Generator  PFAS Feasibility Study

PFAS Feasibility Study  Booster Station Design

Booster Station Design  Value Discovery Program

Value Discovery Program