Written by Tamas Mayer, Architectural Engineer

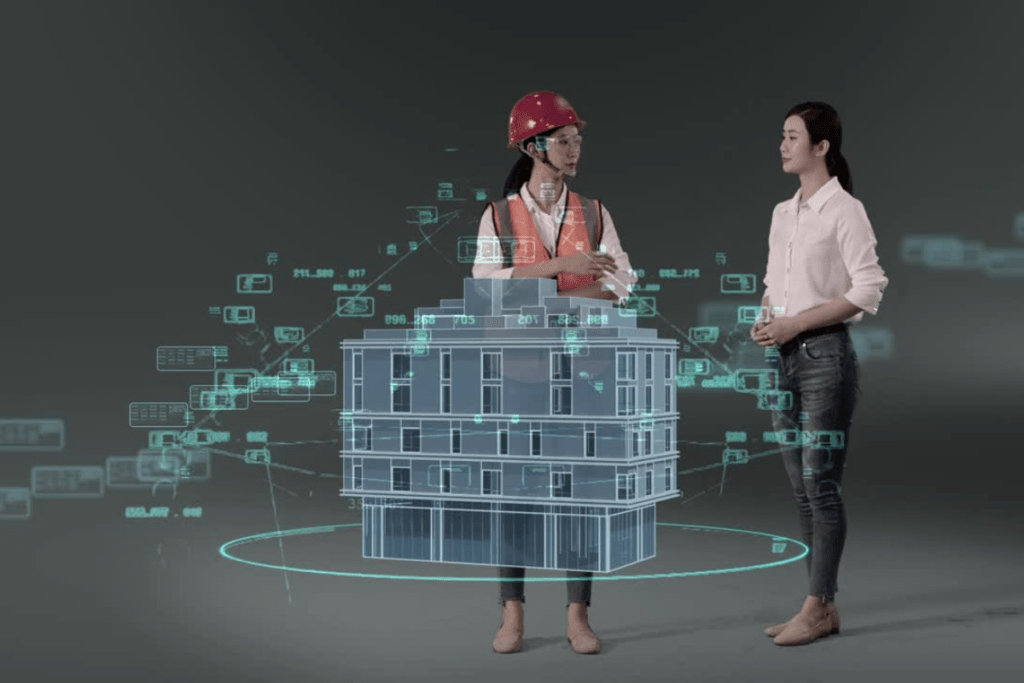

CAD is dead and BIM is the future. There’s a term called ’BIM’ floating around the water industry, especially in the engineering community. Have you ever wondered what BIM is and what value it brings to water & wastewater treatment projects?

Why is it that engineering firms who do design and consider themselves competitive (or even mediocre) on free markets have already converted from traditional CAD designs to BIM modeling? And why “simpleton” CAD will cease to exist in 5-10 years MAX in most (or all) engineering industries?

The short answer is – as in most cases – “time is money and certainty is time.” Income for a privately owned company is the condition of existence. Let’s walk through how engineering firms and asset owners are using BIM in real life to improve their business position – using an imaginary interview of a forward-thinking Civil Engineer at a design expo:

Interviewer: Hey there! If you have 10-15 min to talk, may I ask why are you participating in today’s expo?

Civil Engineer: Of course, it is because today’s topic is best engineering practices and BIM design.

Interviewer: Oh, so I assume you are an engineer, and it seems you also know BIM! Great! Could you tell me a bit about what sets CAD and BIM apart, and how you got familiar with both? I know it is a huge topic, but could you sum it up somehow? Let us start with how you became familiar with Computer Aided Design, please.

Civil Engineer: So first at my company we started using 2D CAD approx. 12 years ago. It was great at that time, but we did the same thing as previously with ink and ruler but this time on PC. We still had to draw each line manually and type in all the fabrication instructions per object as well as various project and client data per drawing, but we could copy-paste a lot at least. Simple objects – requiring the creation of only 2 or 3 projections or related docs – were okay this way it saved us a lot of time, but the design of complex objects – with 5 to 100 related projections and documents – remained a hassle. If we had to modify a single thing, we had to do that consistently throughout all 100 documents one by one, so we still struggled a lot to keep the clients’ everchanging demands and very tight design deadlines, not to mention when we progressed from one design stage to the next one we more or less had to start from scratch having made tons of inconsistencies in our hurry to keep up with the pace. From today’s perspective, I do not think that I could go back to that stage ever.

Interviewer: I see. And after 2D CAD you moved straight on to BIM?

Civil Engineer: No, not at all, first there came the 3D CAD.

Interviewer: Really? Surprisingly, I thought 3D CAD was quite unpopular. How come you have not skipped it?

Civil Engineer: At that time, the main profile of our company was the design of highly engineered, prefabricated steel connections for large-scale mechanical devices e.g., cranes, hydraulic presses, and bridge joints. The most significant “win” using 3D CAD was that we had to build the oftentimes very complex geometry or system once and without drawing even a single 2D line we could generate hundreds of projections of the object in question for eventual assembly works… as well as provide the electronic format, direct geometry output for CNC machining. But unfortunately, we still had to add all the non-geometric data and calculate all the material quantities of our designs manually first. Later the software also did some calculations for us. Building 3D models was hard at first so I see why some companies might have skipped this step, for us simply this was the only way forward. We have managed to raise our design complexity and detail level more than 10-fold in the same amount of time with fewer discrepancies in our documentation than ever before. Thanks to this, our company has become quite a prominent one in the field.

Interviewer: Wow, I never thought about it from that perspective but now that you told your story about it, it seems completely reasonable concerning the design software evolution and application perspective. But now I think we arrived at the BIM stage finally, so please try to sum up the difference between 3D CAD and BIM models.

Civil Engineer: Well, the key difference is that a BIM model is an advanced 3D CAD model infused on the component level with any kind and amount of engineering information. So upon the creation of geometric data, we can inject any further physical information into it. Not just materials, or a volume formula, but its conductivity, it’s chemical composition, or even its different mechanical moduli or properties. It is the closest virtual twin of any physical object in existence, and the nicest of all: the data can be added step-by-step along with the progression of geometric design – always catering exclusively to specific design and client requests. This added data then can be extracted at any time in any projection or schedule. These objects being the perfect virtual vessel of both geometry and non-geometric information can be used universally in ways that were unimaginable with previous methods: design documentation, vast array of simulations, construction and/or production cost and time analysis, value engineering, life cycle assessment …really the list goes on and on. If we alter or delete any information in any projection or documentation, data gets automatically updated or deleted everywhere throughout the entirety of the project, if the system is well-built it can hardly contain discrepancies or “left-over” dump data. BIM objects “have a sense” of what they are and how they should behave.

Interviewer: Do you think it is necessary to build such complex systems? What if one only needs preliminary designs? Why would one need all of this?

Civil Engineer: My answer to your first question is no. It is not necessary, but that is the whole point of BIM – that you are in total control of the level of detail or information that you wish to encapsulate in your model depending on the time you want to invest. Even if you want to do a preliminary design only, a solid BIM model enables you to do it in quality so that the very BIM model can be the rock-solid basis of any possible, further design development or sophistication occurring in later phases, while never having to worry about data loss or inconsistency. Time is money – and is even beyond describable value – and certainty is the design time spared. No force can stop the BIM transition saving time and providing certainty, and therefore trust.

Interviewer: Huh… there is quite a bit to digest here. Thank you. One last question please and then I let you go: if you had only 3 wishes for the ’perfect’ BIM model what would those be?

Civil Engineer: 1st: Precise and Concise Data Management: Well-defined, well-organized engineering-related data structure, appropriate choice of LOD (information + geometry), and keeping excessiveness and entropy at the lowest level required. Universal single-source data is of primary importance as well as appropriate data grouping.

2nd: Highly Accessible Interdisciplinary Data: Make data readable, searchable, logically filterable, modifiable, and linked to a virtual object. Any “projection” of any information object should be universally updated throughout the whole project automatically, irrespective of object location within the project or of the exact “projection” the modification is introduced throughout.

3rd: Capacity and Compatibility for Further Improvement: Accommodation of the possibility of smooth design phase transition: never having to reinitiate a design from scratch twice. Being able to dynamically refine detail and information levels as required.