How Genetic Algorithms can be used for Engineering Designs

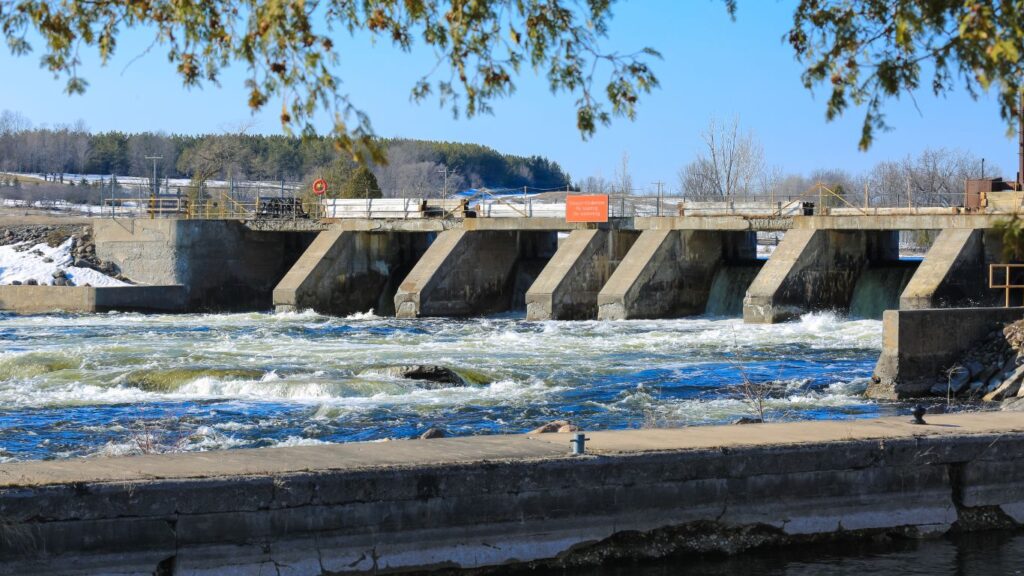

Biological wastewater treatment exists because microorganisms have been developing for millions of years to be able to utilize contaminants from water. The first wastewater treatment plants were built around this feature of nature more than 100 years ago. These tiny creatures are still evolving from generation to generation to adapt better to their environment and as a result, get us clean water.

However, as the world evolves, wastewater treatment must adapt by completing a number of processes. Including biological wastewater treatment as well as primary measures. Primary and secondary wastewater treatment are the two basic kinds. The primary treatment is a straightforward procedure for removing suspended solid waste and lowering its biochemical oxygen demand in order to boost dissolved oxygen levels in the water. Primary is the use of screens and garbage rakes to remove bigger objects. It’s also the grit removal method. Primary treatment decreases biochemical oxygen demand by around 30% and suspended solids by up to 60%, according to estimates. As a result, the water must be treated once more to eliminate any remaining pollutants.

This is when secondary treatment enters the equation. Complex biological processes are used in secondary treatment to remove organic matter that was not removed during primary treatment. You’re relying on biology and microbes to consume and eliminate other pollutants. There are many different types of biological wastewater treatments. However, depending on the situation, each treatment can be classified as aerobic, anaerobic, or anoxic depending on whether or not oxygen is present.

Past Industry Challenges

Over the years, improvements and developments in wastewater treatment have increased. Some have evolved into new commercial techniques, such as granular sludge, membrane bioreactors, sulfur conversion-based bioprocesses, and biofilm reactors.

Computer scientists have been trying to mimic nature’s selection process to solve complex optimization problems since the 60s. The basic idea is to define a starting population of candidate solutions, each of them with its properties. There is also a fitness formula set telling us the goal that needs to be reached. The algorithm will use selection, crossover, and mutation to create a new generation. Each new candidate will have a fitness value and the better value properties will be the parents of the next generation. The algorithm finishes after the goal fitness level have been reached or the maximum generation number is achieved.

Solutions for Engineering Design Processes

So, how may this new evolutionary wave be applied to wastewater treatment? At Transcend we are automating preliminary engineering design creation for wastewater treatment plants. We are utilizing a genetic algorithm to find the optimal building arrangement for the site.

Based on the influent data and effluent limits, Transcends design generator (TDG) first goes through the process and mechanical design steps and determines the necessary assets and their parameters. For example, size, margin, influent, and effluent flow direction. The next step is to find the optimal site arrangement. Transcends design generator fitness formula takes into consideration the building size, orientation, margin, and looking for the shortest connection between the buildings without any overlapping.

It was developed not just for greenfield applications but can also be taken into account the site boundary and existing assets on site.

This platform was created to aid engineers in producing various designs while maintaining complete control over their design process by configuring each application. It is all genetic algorithms. Starting with one building arrangement and changing it from generation to generation to create a slightly better one. TDG’s algorithm evaluates 20 million candidate solutions to find the best layout, and it is all conducted in 5 minutes.

Transcend your future today!