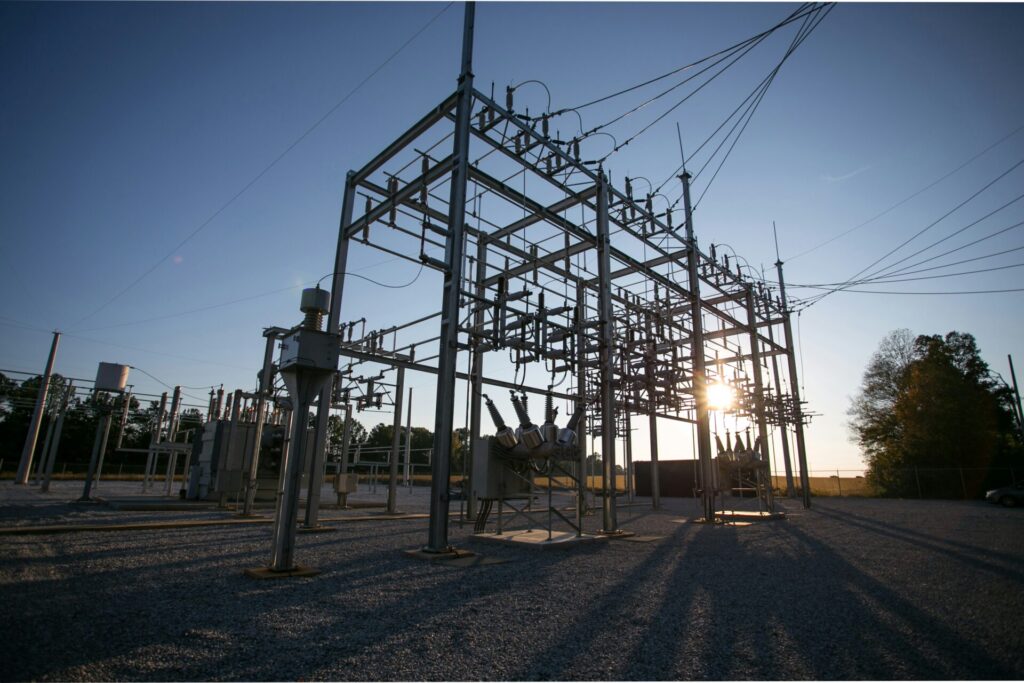

Electrical substations and 500 kV transmission lines are critical components in the efficient transportation of electricity over long distances. In the US alone, there are over 55,000 substations! These high-voltage lines significantly reduce energy losses, making them indispensable for modern power grids. Integrating these lines into substation design ensures that electricity can be distributed efficiently and reliably, supporting the stability of the entire grid.

In this blog post, we’ll dive into the components, applications, and future trends, driving the innovation and design of electrical substations with 500 kV transmission lines. But first, let’s explore what a 500 kV transmission line is.

What is a 500 kV Transmission Line?

A 500 kV transmission line is classified as an extra-high voltage (EHV) power line, capable of transmitting large amounts of electricity over vast distances with minimal losses. By operating at such high voltages, these lines reduce the current required for power transmission, which in turn decreases resistive losses and enhances overall transmission efficiency.

Key Components of 500 kV Transmission Lines

A 500 kV transmission line consists of several essential components that ensure efficient and reliable power delivery over long distances.

Conductors

Conductors are the materials through which electricity flows. Typically made of aluminum or aluminum alloy, sometimes reinforced with a steel core, these materials are chosen for their excellent conductivity and strength. The selection of the conductor material plays a crucial role in the efficiency and reliability of the transmission line.

Insulators

Insulators support the conductors while preventing the unwanted flow of electricity to the ground or other structures. Common types of insulators include porcelain, glass, and composite insulators. These components must withstand high voltages and environmental conditions, ensuring the safe operation of the transmission line.

Transmission Towers

Transmission towers are the structures that support the conductors at safe heights above the ground. Designed to withstand mechanical stresses from wind, ice, and the weight of the conductors, these towers come in various configurations depending on the specific requirements of the transmission line route.

Substations

They play a vital role in stepping down the voltage from 500 kV to lower levels suitable for distribution to homes and businesses. Substations contain transformers, circuit breakers, and other equipment necessary for managing and controlling the flow of electricity.

Applications of 500 kV Transmission Lines in Substation Design

500 kV transmission lines play a pivotal role in the design and functionality of substations, impacting grid interconnection, electricity delivery, and the strategic layout of high-voltage equipment.

Interconnecting Power Grids

500 kV transmission lines are crucial for interconnecting regional power grids, enhancing grid stability and reliability by allowing power to be transferred over long distances to where it is most needed. This interconnected infrastructure plays a critical role in meeting the growing energy demands of modern societies efficiently and sustainably.

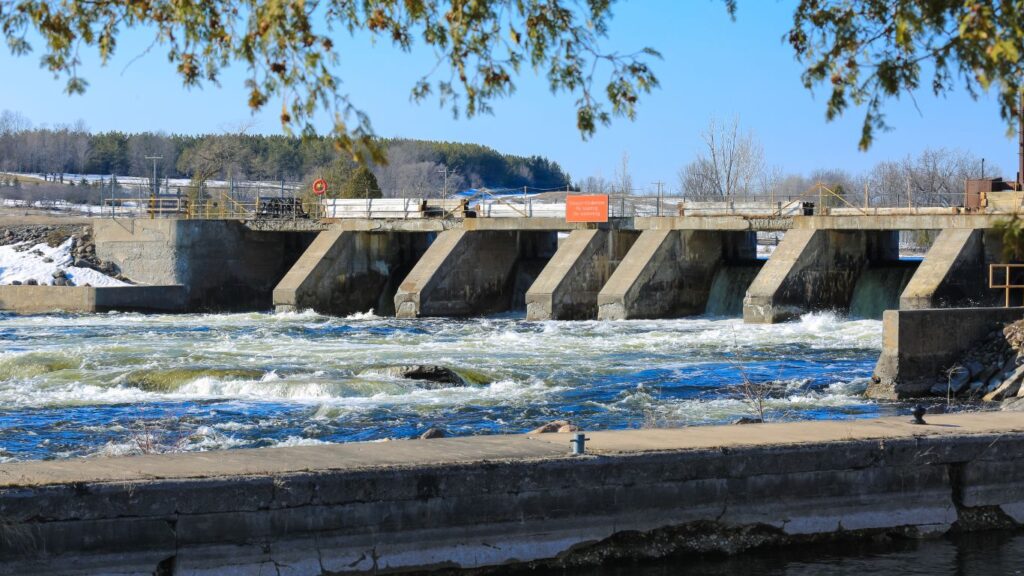

Electricity Delivery

These lines efficiently transport electricity from generation sites, such as power plants or renewable energy farms, to substations. From there, the power is distributed to various regions, ensuring a stable and continuous supply of electricity. These high-voltage lines can carry large amounts of electricity over long distances with minimal loss, ensuring that power reaches substations located far from the source of generation.

Substation Layouts

Designing substations to integrate 500 kV lines involves careful consideration of layout and equipment placement to optimize performance and safety. Substation layouts must be carefully designed to accommodate the arrival and departure of high-voltage lines. This involves positioning transformers, circuit breakers, and other equipment strategically to facilitate smooth operation and maintenance. Ensuring proper clearances and efficient routing of high-voltage lines within the substation is crucial for safety and operational reliability while minimizing energy losses and maximizing the throughput of electricity.

Safety and Maintenance

Ensuring the safety and reliability of 500 kV transmission lines involves rigorous maintenance practices and adherence to stringent safety measures to prevent electrical faults and ensure operational integrity.

Regular Maintenance Practices

Regular inspections, often conducted using thermal imaging, help detect potential issues such as overheating that can indicate impending failure or faults in the transmission line components. These inspections allow maintenance crews to proactively address issues and prevent unexpected outages. Corona discharge detection is another critical practice for identifying insulation breakdowns and ensuring the overall safety of other electrical anomalies that could compromise the safety and efficiency of the transmission line. Early detection allows for timely repairs or replacements, ensuring continuous operation and safety.

Safety Measures

Ensuring proper clearances between conductors, towers, and other structures is essential to prevent electrical faults, arcing, and potential hazards to personnel. Clearances are meticulously calculated based on voltage levels and environmental conditions to ensure safe operation and compliance with regulatory standards. Additionally, minimizing electromagnetic interference protects the transmission line infrastructure and surrounding environment from potential hazards. Shielding and grounding measures are employed to mitigate EMI, ensuring reliable operation and reducing the risk of disruptions caused by external factors.

Technological Innovations and Operational Challenges

The field of 500 kV transmission lines is continually evolving, with technological innovations enhancing efficiency and reliability. However, operational challenges demand robust design and maintenance strategies to address environmental and mechanical stresses.

Innovations

Innovations in 500 kV transmission lines can be observed in the materials used, the designs of the insulators, and the efficiency of real-time monitoring systems.

Conductor Materials

Innovations in conductor materials, such as high-temperature superconductors and composite materials, are enhancing the efficiency and capacity of 500 kV transmission lines. These materials reduce electrical losses and increase transmission capacity, improving overall grid performance.

Insulator Designs

Improved insulator designs incorporating advanced materials and coatings enhance the reliability and longevity of transmission lines. These innovations mitigate issues like corona discharge and pollution flashover, ensuring stable operation under varying environmental conditions.

Real-Time Monitoring Systems

Real-time monitoring systems equipped with sensors and analytics enable continuous assessment of transmission line conditions. These systems provide early detection of faults, degradation, or anomalies, allowing operators to implement timely maintenance interventions and optimize operational efficiency.

Operational Challenges

Here are a few operational challenges that we had to take note of:

Mechanical Stresses

Environmental factors such as wind, ice loading, and temperature fluctuations impose mechanical stresses on transmission line structures. Designing robust towers and conductors capable of withstanding these stresses is crucial to maintaining reliability and safety.

Maintenance Strategies

Effective maintenance strategies are essential to mitigating operational challenges. Regular inspections, predictive maintenance based on data analytics, and proactive repairs are key to minimizing downtime and ensuring an uninterrupted electricity supply.

Environmental Compliance

Compliance with environmental regulations, such as minimizing electromagnetic fields (EMFs) and preserving wildlife habitats, presents additional operational challenges that require innovative solutions and careful planning. This leads us to the next topic for discussion.

Transcend is committed to transforming the power substation design process with our innovative software, the Transcend Design Generator. Utilizing cutting-edge technology and data-centric analysis, we help utilities and engineers explore numerous design alternatives during the capital planning and initial design stages.

Environmental Impact and Sustainability

How do 500 kV transmission lines contribute to environmental sustainability? They contribute to enhancing environmental sustainability by minimizing waste, optimizing resource consumption during design and construction, and facilitating the efficient transmission of electricity. By leveraging advanced software tools and adopting environmentally conscious practices throughout the lifecycle of transmission projects, stakeholders can contribute to a more sustainable energy infrastructure that meets the needs of present and future generations.

Future Trends in 500 kV Transmission Lines for Substation Design

The future of 500 kV transmission lines is poised to integrate advanced technologies and enhance efficiency, reliability, and sustainability in energy distribution systems.

Integration with Renewable Energy Sources

Future developments in 500 kV transmission lines will focus on seamless integration with renewable energy sources. These transmission lines will play a critical role in transporting electricity generated from wind, solar, and other renewable sources located in remote areas to urban centers and industrial hubs. This integration aims to support the global transition towards a low-carbon economy by facilitating the reliable and efficient distribution of green energy.

Advanced Grid Technologies

Smart grids represent a significant advancement, incorporating real-time data and automation to enhance grid management and reliability. These technologies enable utilities to monitor transmission line performance, predict and respond to potential issues proactively, and optimize energy flows to meet demand efficiently. Smart grids also support demand response programs and grid stability initiatives, contributing to overall energy efficiency and resilience.

AI and Machine Learning Technologies

AI and machine learning technologies will play a crucial role in the future of 500 kV transmission lines. These technologies will enhance automation in the design, monitoring, and operation of transmission infrastructure. AI algorithms can analyze vast amounts of data to optimize transmission line routing, predict maintenance needs, and detect potential failures before they occur. Machine learning models can improve fault detection and response times, thereby increasing the reliability and lifespan of transmission assets.

Community Engagement and Resources

Expanding community support and educational resources is vital for the ongoing development of the power transmission sector. These efforts promote public awareness, encourage collaboration, and facilitate continuous learning among stakeholders. On the one hand, engaging communities through outreach programs, public forums, and educational campaigns helps build an understanding of the role transmission lines play in delivering reliable electricity. On the other hand, community engagement and the collaborative approach accelerate innovation and promote the adoption of new technologies and sustainable practices in transmission line design, construction, and operation.

Industry-specific courses, certifications, and workshops offered by educational institutions and professional organizations ensure that engineers, technicians, and managers stay updated on industry trends, regulatory requirements, and technological advancements. Continuous learning enables professionals to implement best practices, optimize performance, and enhance the reliability and efficiency of transmission networks.

Conclusion

500 kV transmission lines are integral to the design and operation of modern electrical substations, aiding the efficiency and reliable transport of electricity. As technology advances, these lines will continue to evolve, integrating with renewable energy sources and smart grid technologies to meet the future demands of the power industry.

Using the Transcend Design Generator revolutionizes how electrical engineers harness generative design capabilities to assess a wide array of substation component choices. This cutting-edge software considers critical factors to yield diverse design options you can rely on.