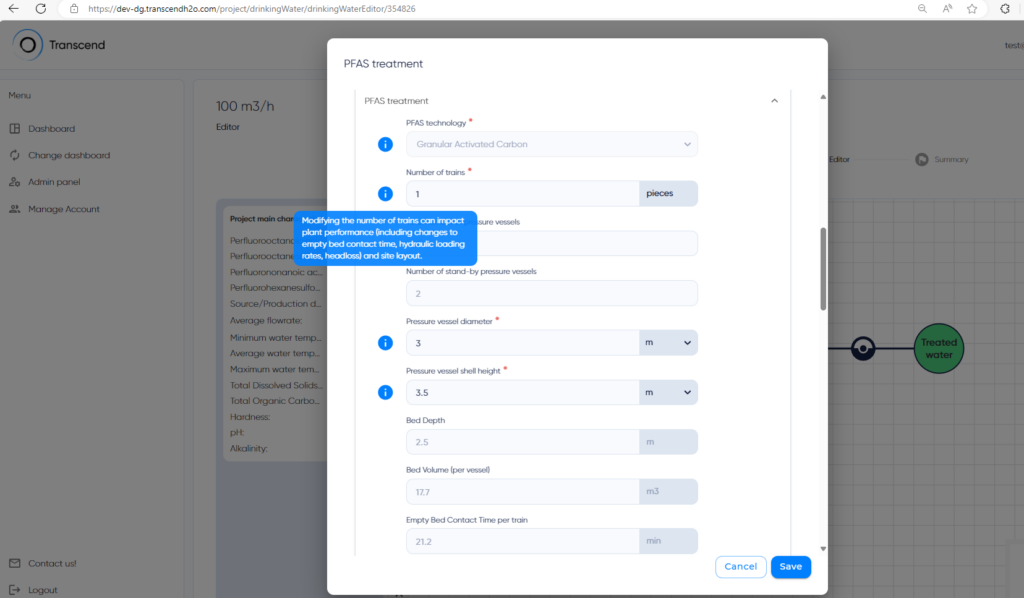

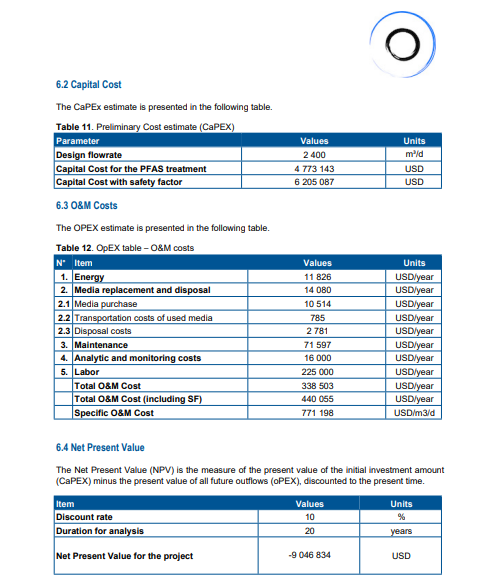

Utilities and their ECs face the daunting task of optimizing PFAS removal processes while considering factors such as media change requirements and transportation costs. GAC treatment design is now available in the Transcend Design Generator to streamline the design process, enabling quicker decision-making and cost estimation.

In the ever-evolving landscape of regulatory compliance, the Environmental Protection Agency (EPA) continues to drive forward its strategic roadmap, focusing on targeted PFAS removal both at the source and in exposed bodies such as soil and water. As utilities and their Engineering Consultants (ECs) grapple with the challenge of optimal vessel configuration, sizing, and site arrangement for PFAS removal with Granular Activated Carbon (GAC), a new solution has emerged to streamline the process.

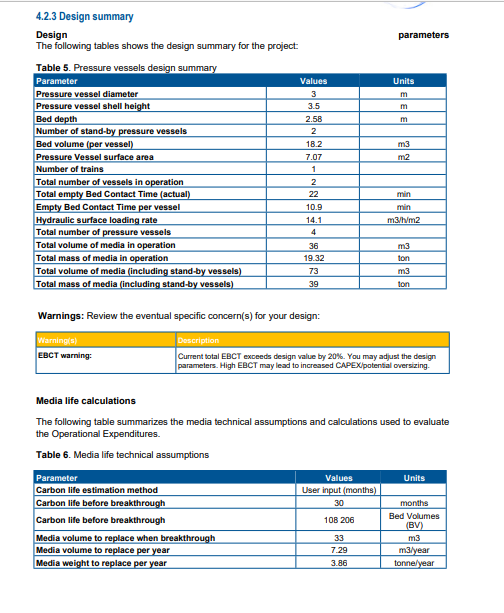

We are thrilled to announce the release of a groundbreaking feature in the Transcend Design Generator that revolutionizes PFAS removal facility design. With this new capability, utilities and their ECs can now effortlessly size a GAC system, determine its optimal location within their site, and obtain crucial operational and capital expenditure estimates. By simply providing site information, basic flow parameters, water quality data, and design preferences, users can generate a comprehensive PFAS removal facility design with just a few clicks.

This new feature adds GAC design capability for PFAS removal, allowing users to input essential parameters and preferences to generate a complete facility design. The outputs include civil drawings, 3D BIM models, OPEX tables, equipment lists, process flow diagrams, and technical description reports, providing a holistic view of the proposed PFAS removal system.

The EPA’s strategic goals now incorporate PFAS removal, reflecting a commitment to addressing these persistent contaminants. Our addition of pressure vessels for GAC treatment offers a practical solution for medium to large-sized utilities facing numerous PFAS-contaminated sites. With PFAS-related process units designed to accommodate proof of concept and trial periods, utilities can navigate regulatory challenges with confidence.

In conclusion, TDG’s new GAC design capability represents a significant advancement in addressing PFAS contamination. By simplifying the design process and providing comprehensive insights, we empower utilities and their partners to meet regulatory requirements and safeguard public health more effectively than ever before. Visit our platform today to experience the future of PFAS removal technology.

Contact us for more information or try it for free today in GenExplore!